Diamonds are for Etching

December 3, 2015

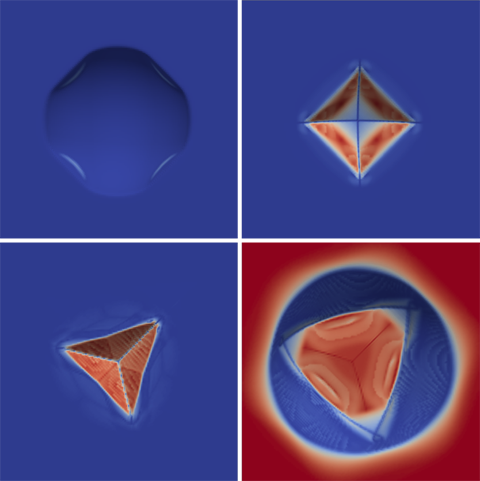

The different shapes you see above were created in a process called electron beam-induced etching using different gases, including ordinary water vapor. When water vapor is introduced into the etching chamber, some of the molecules stick to the diamond's surface, in a process scientists call adsorption. The water-coated surface is then bombarded with an ultrafocused beam of electrons. These electrons by themselves don't have enough energy to carve away the diamond; instead, they tear apart the chemical bonds that hold together the hydrogen and oxygen of the water molecules on the surface. The oxygen molecules can then re-bond with the carbon on the surface, freeing that carbon atom from the lattice and leaving a pit where it was. Surfaces that are textured at the nano-scale can have physical and electromagnetic properties that are otherwise unseen in nature, like superhydrophobicity. The symmetries of the structures formed by this technique depends on the gas used, promising a wide range of potential structures with diverse applications.