Science of a Shipwreck: Costa Concordia

Nearly one year ago, disaster struck off the coast of Italy. The Costa Concordia cruise ship hit a rock close to the Italian shore, ripping open 160 feet of the ship's steel. Thirty people died in the disaster, and dozens more were injured. Although the remaining passengers were rescued, other significant threats linger.

One year later, the steel behemoth still sits partially submerged just off the coast. Salvage efforts in the past have used a variety of destructive methods, but the Costa Concordia presents several unique challenges. It’s the largest capsized passenger ship in history, and it ran aground in a protected marine environment.

Explosives could dislodge the ship, or operators could slice the ship into pieces with gigantic chain saws. Both of these options, however, could easily devastate the surrounding environment and tourist industry. Instead, the Italian government selected an expensive two-step process that’s never been done on this scale: parbuckling and re-floating.

The Costa Concordia wreckage.

The Costa Concordia wreckage. Image Credit: Rvongher via Wikimedia Commons.

Physics of Parbuckling

Salvage operators have already secured the massive ship in place, and they plan to rotate it off of its side. The ship won’t simply float once it’s turned on its side, however; water has flooded much of the ship’s interior, reducing its buoyancy.

Instead, the salvage team is building an underwater platform that the ship will rest upon after the rotation. Once the ship has been righted, a small fraction of it will peek above the surface while it sits atop the artificial support.

Rotating such a large amount of submerged steel will prove quite difficult, and the team must strike a balance between having enough force to rotate and using excessive force that might damage the ship. Using strong cables, the team plans to slowly roll the ship off of its side over the course of a couple days.

“They have to be very careful that they don't place the hull under high stresses,” said Jeff Stettler, a salvage expert and retired Commander in the U.S. Navy who is not working on the Costa Concordia wreck removal.

Partially to help rotate the ship, operators will attach sponsons — large, box-like structures — to the side of the ship that’s above water. These sponsons will eventually help re-float the ship, but they also act like a cantilever, adding weight and making the rotation easier, according to Stettler.

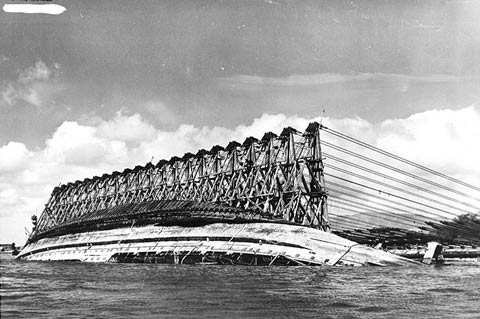

Cantilevers are beams that are only supported on one end, and naval experts have used this cantilevering effect before to salvage ships. After the bombing of Pearl Harbor in the 1940’s, the U.S. military parbuckled the capsized USS Oklahoma in a very similar fashion. Operators attached cables to structures fitted onto the ship before rotating it back to an upright position, as seen below.

Parbuckling was used during the salvage of the USS Oklahoma during WWII. Image Credit: NHHC

Parbuckling was used during the salvage of the USS Oklahoma during WWII. Image Credit: NHHCNo one’s parbuckled a passenger ship as large as the Costa Concordia, however.

“It’ll be very interesting to see how smoothly it goes,” said Stettler.

Floating Once Again

Once engineers rotate the ship back to its seaworthy stance, they have to give it enough buoyancy to float again. For a ship to float, the buoyant force of the seawater must equal the gravitational force pushing the ship downward – its weight.

According to Archimedes’ principle, the buoyant force equals the weight of water displaced by a floating object. Before the disaster, the Costa Concordia’s enormous volume displaced enough water to counteract its massive weight. Now, however, water has inundated much of the ship’s interior — water that the ship no longer displaces.

In short, the ship has lost buoyancy. To restore some of that buoyancy, divers and engineers have likely patched the interior as best as they can. But the ship will need significant help from the outside as well. That’s the secondary and more important purpose of the box-like sponsons fixed to the side of the ship.

After righting the ship, the salvage team will attach sponsons to the other side of the ship, giving it a symmetric bulge. Although the sponsons will initially fill with seawater, engineers will use hydraulic pumps to fill the sponsons with air.

Once filled with air, the sponsons will displace more water, providing external buoyancy; this external buoyancy will balance out the buoyancy lost to the flooded parts of the ship. Once the ship’s floating again, the team will tow the wreckage to a shipyard and scrap the ship for its metal.

This re-floating should be more straightforward than the parbuckling, according to Stettler.

“Once upright and on that platform, it's just a matter of time to get enough buoyancy,” said Stettler.

Video detailing the ongoing wreckage removal

The salvage team hopes to finish the parbuckling, re-floating, and towing of the Costa Concordia in the summer of 2013. Hundreds of millions of dollars are being poured into the project, and hundreds of workers have been working around the clock for months.

Stettler warns that salvages and wreck removals never go exactly according to plan. Nonetheless, he’s cautiously optimistic about the endeavor, citing the project operators’ expertise, careful design and modern technology.

“I’m pretty confident it’ll happen,” Stettler said.

—Brian Jacobsmeyer